While the UK has a rich industrial heritage, it is often overlooked that the origins of large-scale manufacturing can be traced directly back to the Midlands.

Birmingham was described as “the first manufacturing town in the world” as far back as 1791, and quickly earned a reputation as a city of multiple trades. This, in turn, gave rise to various factories and innovative manufacturing plants throughout the entirety of the Midlands, with some of the most iconic brands utilising cutting-edge engineering processes to produce goods enjoyed all around the globe.

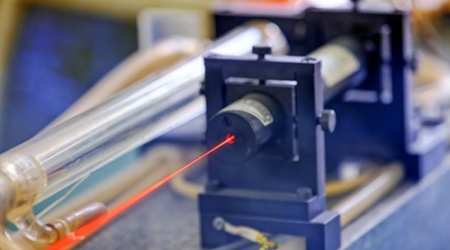

From brewing to textiles, ceramics and automobiles, at one stage the Midlands has been home to all these key industries – and today, the area continues this trend, with laser cutting and first-class engineering projects all situated within. There’s never been a greater time to enrol in STEM studies in the area, with a plethora of engineering classes, apprenticeships and degree courses to choose from in some of the most highly regarded educational establishments in the country.

In this article, we’ll look at some of the most important contributions the Midlands has made to the UK manufacturing industry, as well as focusing on what the future holds for this industrial stronghold.

Carpets

Kidderminster-based carpet-maker Brinton’s has been producing floor coverings for over 230 years. At the peak of its performance, the firm had no less than 25 factories within the town and employed approximately 15,000 people. While production has scaled back somewhat since its heyday, the carpet manufacturer still produces high-quality goods and employs over 500 staff, with many predicting that post-Brexit market changes could give the industry a much-needed boost.

Cookers

While many associate the Aga range with Sweden, the company has had a foundry and factory in Shropshire since the 1940s, which continues to employ over 350 people. Aga cookers are iconic and despite declining interest during the recession, renewed popularity of the brand has led to increased manufacturing since 2012. These devices are a masterclass in design and are sought after for their reliability and durability – proof positive that the demand for engineering in the Midlands is still unparalleled.

Classic cars

The automobile industry has been a constant presence in the Midlands for well over a century. Aston Martin, Jaguar, MG, Land Rover and Morgan all produce vehicles in the area. The cars and vans produced in these factories are sold all over the world, contributing billions to the UK economy. Of course, without skilled engineers it would be impossible to create such high-quality vehicles, and in addition to producing cars we all know and love, there’s some serious automotive research and development going on in the Midlands. In 2011, a hydrogen fuel cell powered vehicle, the Microcab, was unveiled in Coventry. The Microcab is one of many potentially industry-changing vehicles, manufactured right here in the UK.

Black cabs

The iconic black cab also has roots in Coventry. Production on these instantly recognisable hackney carriages began in the early 1960s, with the London Taxi Company producing over 130,000 of these vehicles until production ended in 2012. While public transport trends may have moved on with the rise of car-sharing apps like Uber and Lyft, the Midlands is where it all began for this icon of the road – these cabs were built to last, and many of them are still in use decades after they were manufactured.

Brewing

Industrial-scale beer brewing in the Midlands can be traced back to 1982 when the Birmingham Old Brewery opened its doors. Since then, scores of successful brewers such as The Holt Brewery Company, Mitchells & Butlers, Ansells Brewery Ltd and Davenport’s Brewery have been and gone – while many successful brands including the Aston Manor Brewing Company, Rock & Roll Brewhouse and Ostlers Ales continue to develop beer across the Midlands, with engineers tasked to create and develop safe and efficient systems for streamlined, affordable production.

Armoured vehicles

With a highly skilled and experienced team of engineers, BAE Systems in Telford produces and maintains armoured vehicles used in some of the most dangerous conflicts around the world. It continues to employ local apprentices and graduates for some of the most demanding engineering tasks imaginable, which include developing and manufacturing special plating to protect soldiers from roadside bombs and improvised explosive devices. From design engineers to operational fitters, engineering prowess is in high demand here.

Laser cutting

Since its formation towards the end of the eighties, Nuneaton-based Subcon has gone from strength to strength and is now one of the most successful laser cutting companies in the country. From humble beginnings, the company launched with a 1.2kw 2-axis LaserLab counter system. By the 90s the company had relocated and expanded its technological capabilities.

Today, Subcon is an award-winning manufacturer which makes use of the very latest in laser cutting technology and engineering expertise to continue the trend of innovation in the Midlands.