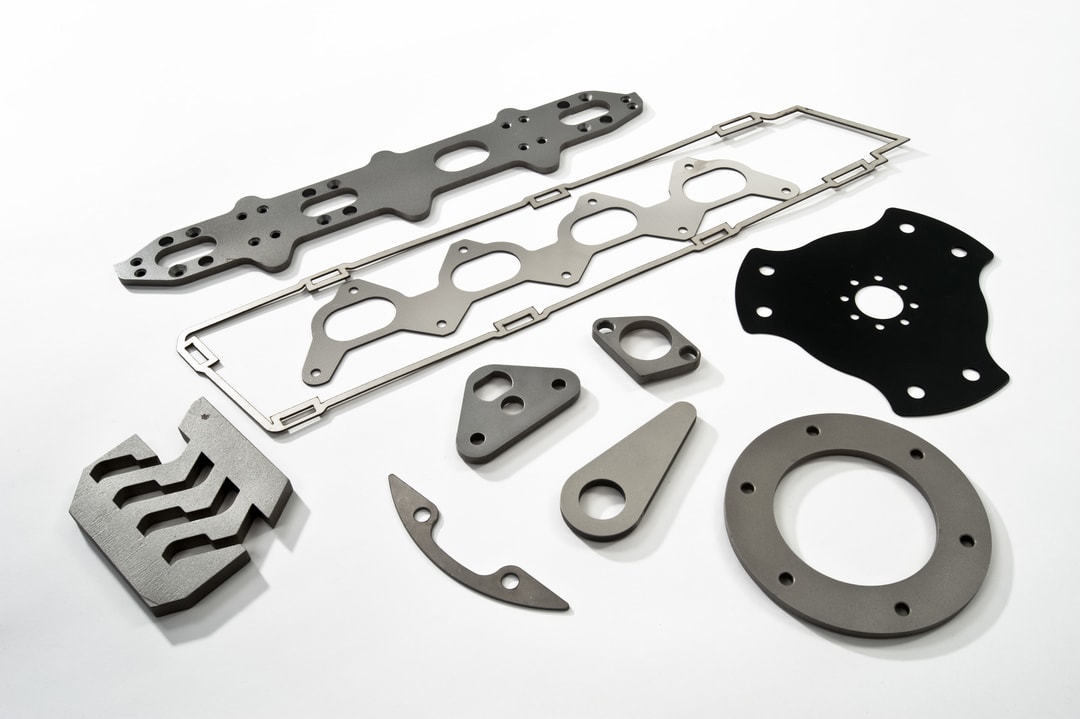

Laser Cutting Galvanised Mild Steel

Our galvanising process ensures your steel parts are protected against corrosion, for durability and performance in harsher environments. Our galvanised sheet and plate undergo a coating process whereby they are dipped in molten zinc, creating a protective metallurgical bond on the material surface.

Subcon Laser offers fibre and C02 laser cutting and secondary fabrication operations on galvanised steel sheet as per your project requirements, ensuring we can meet your subcontracted manufacturing needs with high levels of quality and efficiency.

- Tolerances from +/-0.12mm to 0.5mm, depending on material thickness

- Galvanised steel sheet from 0.5mm to 3.0mm as standard. Thick gauge on request and subject to availability.

- Suitable for material up to 4000mm x 2000mm.

Galvanised Steel Grades

Subcon Laser stocks DX51D grade hot dipped galvanised sheet to BS En 10346: 2015 as standard, providing versatility in a range of environments and applications. We can further source and supply structural base grades such as S280 and above upon request.

Please note, the information provided here is based on general characteristics of DX51D steel.

| DX51D | |

| Chemical Composition | Mild steel coated in a layer of Zinc (Zn) |

| Yield Strength | 140 MPa |

| Tensile Strength | 270-500 Mpa |

Galvanised Steel Vs Zintec

Both galvanised steel and Zintec steel are coated in a layer of zinc, however there are some key differences between the two.

Galvanised steel, commonly achieved through the process of hot dipping, coats the steel in a thicker layer of zinc. While this has benefits as to the corrosion resistance of the material, it is poorer to machine than Zintec.

Zintec steel is achieved through an electrolytic process, and the thin layer of zinc coating it achieves makes it suitable for pressed products. Zintec is not suitable for corrosive environments unless it has undergone a secondary process to enhance its corrosion resistance.

If you’re unsure about the most appropriate steel type for your project, Subcon Laser can advise you on the most feasible option for an efficient and effective production process.

Galvanised Steel: FAQs

Hot dipped galvanised steel is chosen because of its high resistance to corrosion, making it suitable for even harsh environments; other characteristics such as strength are derived from the mild steel grade.