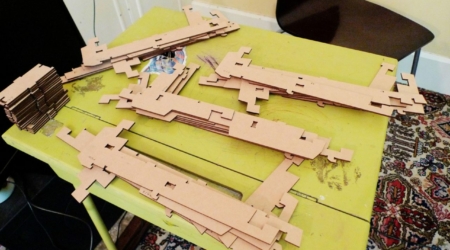

Laser cut clothing is taking the world by storm and we couldn’t be more excited.

Unless you’ve been living under a rock these past few years, then there’s absolutely no excuse not to appreciate the buzz currently surrounding the fashion industry.

From what started out as something the chic designers played around with, the use of lasers in the clothing industry has come on leaps and bounds as mainstream brands such as Topman and ASOS are starting to toy around with the idea.

And that’s just the beginning.

Why laser cut clothing is here to stay

Laser cutting and the textile industry is a relationship that has blossomed in recent years, with laser cut clothing making the rounds across runways across the globe.

Milan? Paris? London? You name it and an item of laser-produced clothing has made an appearance. Come to think of it, it’s hard to think why it took so long for the two industries to team up, but nonetheless we’re happy to see the results today.

Yes it’s true that there was a time when the notion of producing clothes with laser cutting equipment was seen as nonsense, but you’d be surprised by how well the match has worked out.

Rotterdam designer Martijn van Strien has been a catalyst for laser cut fashion in recent times, having launched his own brand with a collection of unisex garments that are cut into intricate shapes.

Today, laser cutting is used for a variety of purposes in the fashion world, whether it’s for the haute couture designs or more mainstream items.

What are the benefits of using laser cut fabric?

Using laser cut fabric has become an immensely popular method of producing designer clothing, with the likes of latex, rubber, leather, cotton and silk all undergoing the laser cutting treatment in recent times.

It’s safe to say the use of lasers in the fashion industry has taken on new levels, but let’s take a look at some of the key benefits laser cutting fabric introduces:

– Speed – one of the most important aspects of working with laser cut fabric is that the overall downtime working on a particular design will be reduced significantly

– Precision – having the ability to consistently replicate an intricate design is an invaluable asset for any fashion designer

– Repeatability – as mentioned, being able to produce high volumes of the same product will definitely help reduce your expenditure in the long run

– Professional finish – using a laser beam on materials such as leather and cotton will help seal in the edges and eliminate fraying, making for a precise finish

– Low risk – the synthetic laser cuts through the fabric with minimal risk, so you don’t have to worry about burn marks.

Why should I care about laser cut clothing?

Well if you have any appreciation for clothing you’ll understand just how important the finite details that precision laser cutting introduces.

Laser engraving refines the surface of the material, which in turn improves the overall quality of the fabric. Essentially what this means is that the the flexibility and precision of the cut is increased tenfold, while the overall time spent working on a design is reduced significantly – an important asset in the textile industry.

If you are a designer, you’ll understand just how important time factors into your schedule, not to mention how it can affect the overall look of the product. Being able to mass produce your designs will also reduce costs in terms of delays and whatnot.

As you may well know, producing an intricate design can be a long and arduous task, while the chances of perfectly replicating that can be slim. What laser cutting does is eliminate that risk and helps you create designs that the competition can only dream of.

How can Subcon Laser help?

When it comes to producing the highest quality laser cutting designs, Subcon Laser are second to none. We offer a comprehensive range of laser cutting services and facilities to support a vast array of industries, so you can count on us no matter the job!

Our unique service has been carefully crafted over the years, combining our vast levels of skill and experience to help make your company grow. It’s because of this why we have been fortunate enough to work with a number of satisfied clients – many of whom are still happy to work with us to this day.

For more information about how Subcon Laser can help your business, don’t hesitate to get in touch with one of our friendly staff today 024 7664 2221. Alternatively you can fill out our contact form and we’ll get back to you as soon as possible.