We had a great day at the Made in the Midlands Expo last week. We talked about our laser cutting service all day and showed off our skills and expertise with a few of the things we’ve made recently. And, even more exciting, the event was covered by NHK, the Japanese equivalent of the BBC!

NHK will be filming us at Subcon HQ later this week too for a documentary about the English manufacturing industry. Their main objective in filming the Made in the Midlands Expo was to capture the ways that Midlands manufacturers promote their businesses.

Japanese manufacturers are concerned about Japan’s aging population and weak economy so NHK’s documentary will give a bit of insight into the way British manufacturers are driven to network in order to meet like-minded companies and generate more business.

There are lots of reasons to be excited about laser cutting in the Midlands and across the UK.

Here are our top three:

-

Introducing the 8kw Trumpf Brightline Fibre

Eighteen months ago, we invested almost £1million in the 5kw Trumpf Brightline. Our further investment of £1.25 million in the 8kw laser and Faro 3D measuring and scanning inspection arm shows our continued dedication to staying at the forefront of our industry. And, even better, this technology will help us to continue to reduce our carbon footprint.

This laser cutter is not only faster and more efficient, it also comes with some optional extras. Naturally, we’ve gone for all of them. Every single one. And we are the first UK company to do so.

This is UK laser cutting at its finest.

Some of the coolest laser cutter features are:

–Dot Matrix Code allows for quick and reliable marking using a standardized industrial code.

–The Titan Package that allows titanium to be laser cut to aerospace standard and specification.

–Smart Collision Prevention means that parts can be cut without micro joints or tagging as the intelligent processing strategy maximises stability.

–Drop and Cut is a feature we have added to continue to reduce our carbon footprint. This technology shows a live image of the offcut inside the machine so that we can place part geometrics directly onto the offcut. This means that even small offcuts can be used more intuitively to reduce waste.

–Mobile Control uses the machine’s own wireless network to transmit images taken by the machine to an iPad via an app. This means that we can monitor the product even while we are away from the machine.

–CoolLine is the coolest of our additional extras – literally! It allows selective cooling during the cutting process so that when we are cutting fine detail into a thick material, the process is significantly more stable.

With all of these features, our 3D measuring capability now compliments our 2D inspection laser scanning systems. And, with both our 2D and 3D laser cutters we are confident that we can provide some of the highest quality, cost effective laser cutting in the UK.

2) Have a look at some of our creations

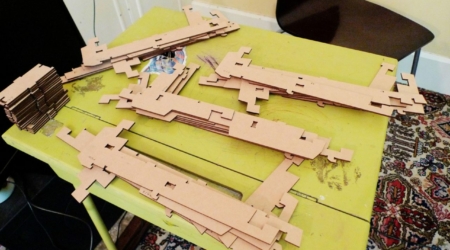

The Made in the Midlands show wasn’t just a great time to reveal our new state of the art laser cutting equipment, it was also a perfect time to show what uses laser cutting can be put to.

At Subcon Laser, we are proud to be able to offer all sorts of custom laser cutting options that let our customers create some amazing things. Because we offer all sorts of complimentary services as well as laser cutting, we can take a project from start to finish all under one, albeit large, roof.

At the MIM expo, we wanted to show off one particular design, this rather futuristic pizza oven.

This oven took us a good while to make what with all the different production techniques it required but it was certainly worth our while! We think it might just be one of the coolest projects we have undertaken and hope to do more like it.

If you missed our favourite space-age pizza oven at the Made in the Midlands expo, don’t worry because you’ll have another opportunity to see it soon.

Which brings us to…

3) The Subcon Show!

After this month’s success at Made in the Midlands, we can’t wait for the Subcon Show. The show is on from the 7th to the 9th of June at the NEC Birmingham and brings together buyers and suppliers from all sectors including:

Automotive

Aerospace

Electronics

Materials

Energy

Rail

Oil and Gas

Defence and Security

With over 300 exhibitors, there is something for everyone. We’re really looking forward to getting stuck in to the three day show and hope to see as many people there as possible!

As we supply to most of the listed sectors and a few more besides, we will have loads to talk about over the three days. In fact, three days might not be enough!

To find out more about the services we provide, visit our website or get in touch.