Brass Laser Cutting

Whilst cutting brass with traditional C02 laser technology poses challenges, Subcon Laser’s state-of-the-art fibre laser equipment ensures we’re able to cut with accuracy, reliability, and efficiency.

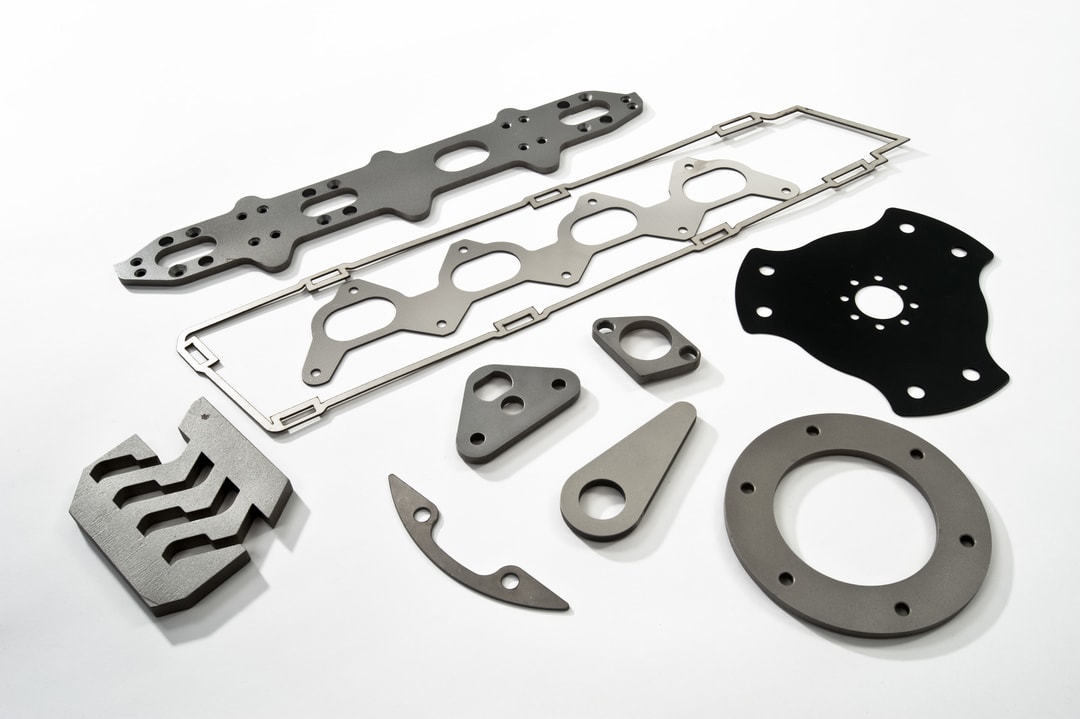

Known for its conductivity and low friction properties, we provide brass components for automotive parts, heat exchangers, electronics and more.

- Tolerances from +/-0.12mm to 0.5mm, depending on material thickness

- Brass is available in thickness from 0.5mm to 40.0mm

- For maximum material dimensions of 4000mm x 2000mm

For this service, Subcon Laser handles manufacturing projects of all sizes and complexities, working with our customers from design feasibility to full production and delivery, determining your needs and meeting them at every step.

Brass Grades

Subcon Laser provides brass in both CZ108 and CZ112 alloys for our operations.

CZ108 is a popular, high-purity brass alloy which is suitable for both hot and cold working processes. This alloy is classified as an alpha brass, due to a lower percentage of zinc in the material.

CZ112, also known as naval brass thanks to its use in marine applications, has a higher percentage of zinc and offers increased strength and corrosion resistance. CZ112 is best suited to hot working.

Subcon Laser can provide advice on the most appropriate brass alloy for your application, if required during initial processing.

Our Processes

Our laser cutting processes utilise Trumpf fibre machinery, enabling us to overcome the obstacles posed by laser cutting brass – namely, its reflectivity. Unlike C02 laser, fibre laser is less likely to be reflected by copper, allowing for the laser energy to be absorbed and melt the material to form a cut.

The machinability of brass makes it suitable for Subcon Laser’s secondary operations. Our comprehensive manufacturing process encompasses a range of operations, from forming and drilling, to CNC machining.

Subcon Laser ensures we’re able to provide a comprehensive and expert service to manufacture laser cut brass parts for all projects, across all sectors.