Copper Laser Cutting

Our investments into the latest laser technology ensure we can expertly handle copper with time- and cost-efficient fibre laser cutting. We utilise Trumpf machinery for a high-quality finish on your laser-cut copper components, facilitated by nitrogen as our active assist gas to prevent any discolouration during the manufacturing process. Oxygen assist gas above 3.0mm gauge.

- Tolerances from +/-0.12mm to 0.5mm, depending on material thickness

- Copper thickness from 0.25mm to 16.0mm

- Maximum material sheet of 4000mm x 2000mm

Throughout our decades of operation, Subcon Laser has been at the forefront of supplementing our capabilities with the latest equipment; this includes cutting-edge fibre technology, which allows us to achieve greater quality and turnaround times, at a better cost, for our customers – even when cutting trickier materials such as copper.

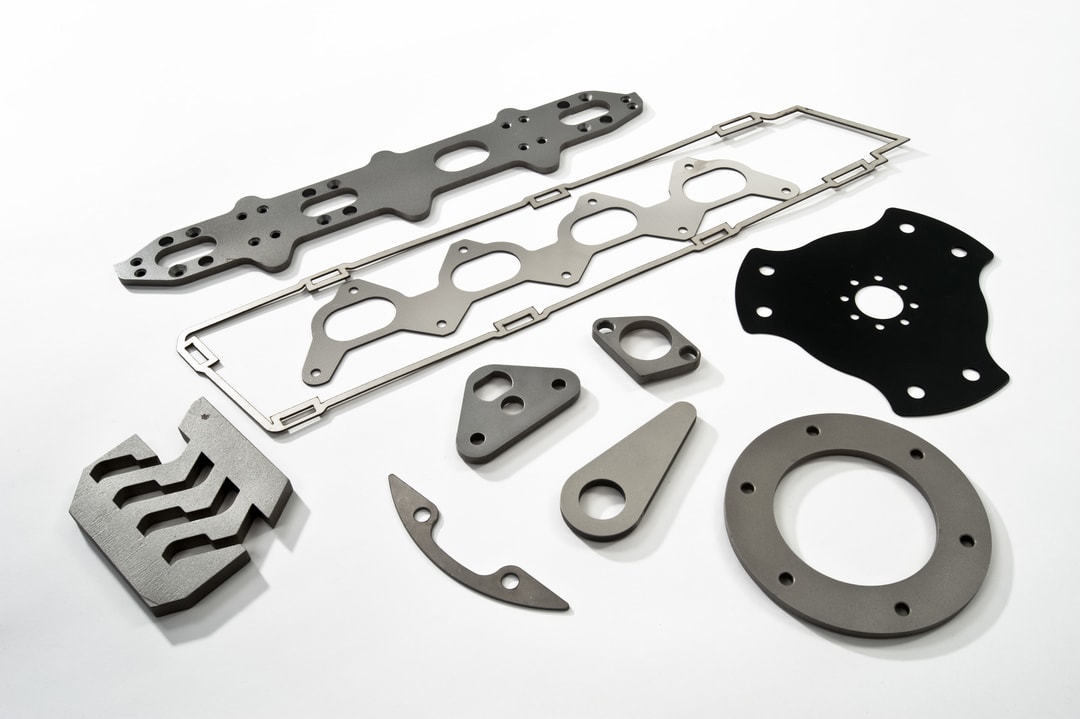

Our ability to handle a wide range of materials for our laser cutting and secondary operations ensures that no matter the specifications of your project, Subcon Laser’s expert team works closely with you to deliver premium laser cut and fabricated parts and components.

Copper Grades

Subcon Laser handles a wide range of copper grades and alloys, including C101, C103, and C106.

Our copper grades offer a high copper content, making them highly conductive, corrosion-resistant, and ductile.

A soft, malleable, and ductile metal, copper is suitable for use in a variety of industries as a conductive and antimicrobial material. This includes electrical wiring, power generation, construction and plumbing, medical equipment, electronics and more.

Copper Laser Cutting: FAQs

On flat laser cut products, our lead times are typically 3-5 days. For flat and formed parts, our lead times are typically 3-7 days. It’s important to note that lead times are live and may differ depending on specification and capacity. Where requested, Subcon Laser are flexible with lead times.