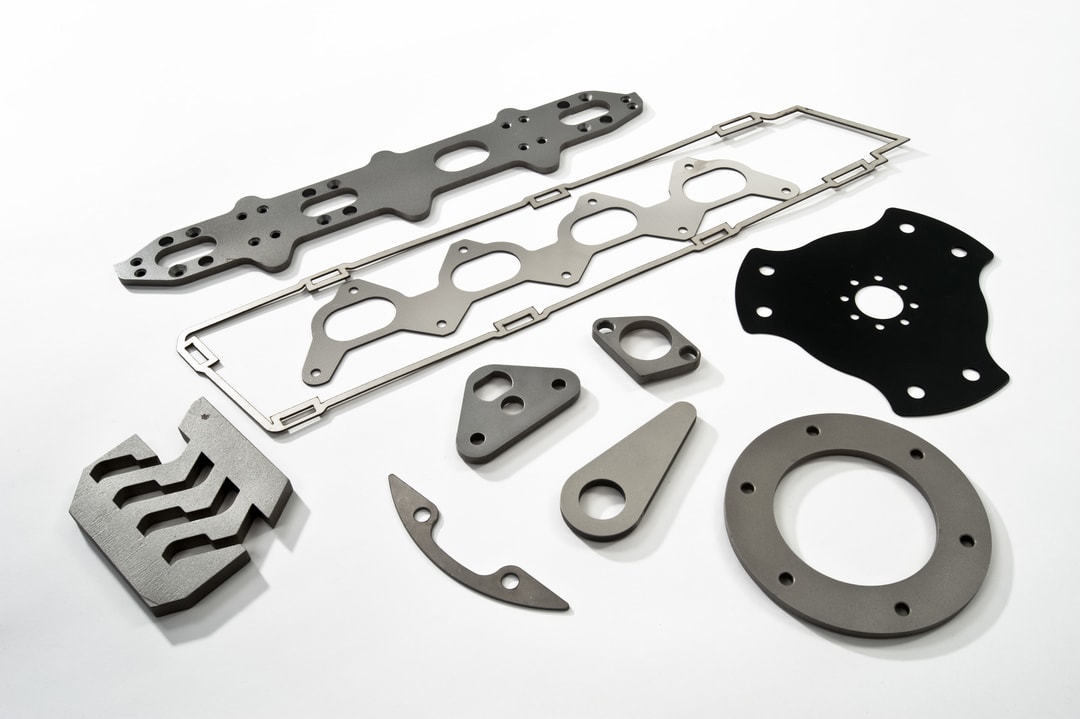

Mild Steel Laser Cutting

At Subcon Laser, quality is paramount when handling our mild steels. Our capabilities to laser cut steel are as follows:

- Tolerances ranging from +/-0.12mm to 0.5mm, depending on material thickness

- Material thickness from 0.5mm to 50mm

- For a maximum material sheet of 4000mm x 2000mm

We offer a varied selection of high-quality, premium steel products here at Subcon Laser.

Using the best steel from the most trusted and established steelworks in the world means that you can relax knowing that you’re in great hands when dealing with us.

Our high-strength steel sheets and plates, from such suppliers like SSAB, thyssenkrupp, TATA steels, ArcelorMittel, POSCO and other, assist us in proving a better performance, reduce residual stress and in essence puts sustainability at the forefront of your product and everything we do.

Not only do we try and make our products as cost-effective for our customers, we are environmentally conscious and friendly too, improving the world we live in.

We supply a range of steel grades, which are available in widths and thicknesses from 0.6mm to 30.0mm. Other products are available on request and our sales team is on hand to best find exactly what you need with no obligation.

Hot Rolled Steel

Hot rolled steel is a popular choice for the laser cutting process due to a higher carbon content compared to cold rolled steel.

Manufactured by processing steel through a rolling mill at temperatures above its recrystallisation temperature, hot rolled steel is known for its malleability and other desirable properties.

Hot rolled steel is a popular choice for the laser cutting process due to a higher carbon content compared to cold rolled steel.

Manufactured by processing steel through a rolling mill at temperatures above its recrystallisation temperature, hot rolled steel is known for its malleability and other desirable properties.

Grades

Subcon Laser’s hot rolled steel grades include S275 and S355, however we’re happy to handle other grades as per customer requirements.

Please note, the information provided here is based on general characteristics of mild steel.

| S275 | S355 | |

| Chemical Composition | Carbon (C): ≤ 0.25%

Silicon (Si): ≤ 0.40% Manganese (Mn): ≤ 1.50% Phosphorus (P): ≤ 0.04% Sulphur (S): ≤ 0.05% |

Carbon (C): ≤ 0.23%

Silicon (Si): ≤ 0.50% Manganese (Mn): ≤ 1.60% Phosphorus (P): ≤ 0.035% Sulphur (S): ≤ 0.035% Nitrogen (N): ≤ 0.012% |

| Yield Strength | 275 MPa | 355 MPa |

| Tensile Strength | 430-580 MPa | 470-630 MPa |

| Elongation | 23% | 22% |

Finishes

Due to its textured surface finish and the surface scale created during the manufacturing process, Subcon Laser provides finishing of hot rolled steel. Our finishes include pickling and oiling to enhance surface finish and increase the shelf life of your product.

Cold Rolled Steel

Subcon Laser also works with cold rolled steel, which provides an improved surface finish and advantageous properties.

Cold rolled steel refers to steel that has been processed through a cold reduction process to achieve specific properties and dimensions.

Grades

Subcon Laser holds CR4/DC01 as standard, however we can accommodate other grades if required by our customers.

Please note, the information provided here is based on general characteristics of CR4 mild steel.

| CR4/DC01 | |

| Chemical Composition | Carbon (C): ≤ 0.12%

Silicon (Si): ≤ 0.45% Manganese (Mn): ≤ 0.60% Phosphorus (P): ≤ 0.045% |

| Yield Strength | 140-180 MPa |

| Tensile Strength | 270-330 MPa |

| Elongation | 28% |

Finishes

Our cold rolled steel can be treated with various coatings and finishes to meet project specifications, including galvanisation to enhance corrosion resistance and appearance.

Mild Steel FAQs

Cold rolling steel provides an improved surface finish compared to hot rolled steel, as well as tighter dimensional tolerances and improved strength and hardness.