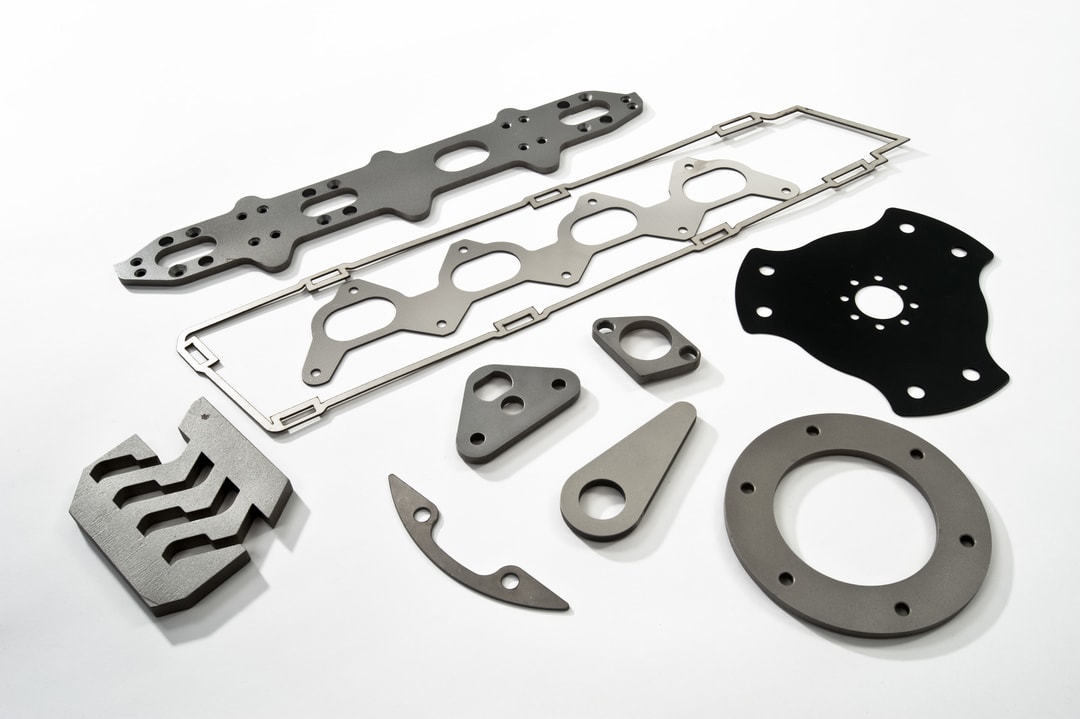

Our Sheet Metal Laser Cutting Service

Specialising in laser cutting, with a wide range of secondary fabrication operations available, Subcon Laser’s complete production service ensures we can cater to a multitude of project requirements.

We offer both fibre and C02 laser cutting for 2D components, with a choice of materials, grades and thicknesses held in stock.

- Tolerances from +/- 0.15mm to +/- 0.5mm

- Material thicknesses from 0.25mm to 50.0mm, depending on material

- Maximum sheet sizes of 4000mm x 2000mm

With over three decades of operation in this sector, Subcon Laser has the industry experience and skill to support our clients at all stages of their project. From initial design feasibility through to full production, we take pride in our customers being able to rely on Subcon Laser’s service to meet their project specifications.

Sheet Metal Materials

We keep a number of sheet materials in stock, including steel, stainless steel, aluminium, copper, brass, bronze and more.

Take a look at our full materials list to see our capabilities and material specifications in detail.

Our Processes

Subcon Laser’s laser cutting department has undergone heavy and continual investment, ensuring we can provide our customers with precision, state-of-the-art CAM/CNC machinery and CAD technology. We’re able to incorporate chamfers and bevels into processes, reducing the need for additional manufacturing.

This results in a time- and cost-efficient process for low and high volume product batches, reducing scrap. With our CoolLine feature on Trumpf laser cutters, we increase reliability – particularly for thick material pate.

For customers requiring further fabrication, Subcon Laser is also able to provide a number of secondary operations. This includes:

- Forming

- Drilling and tapping

- Countersinking

- CNC machining

- Welding

- Laser bevel cutting

- Deburring and vibro-deburring

Quality Assurance

Quality drives our service at Subcon Laser, from our customer service to the delivery of your finished product.

Our laser cutting and manufacturing service is backed by ISO 9001: 2015 for quality assurance, with our products being EN 1090/ UKCA marked. We’re further accredited with ISO14001: 2015 for an environmentally-considerate service.

We provide 2D laser scanning for quality inspection services, completed by a FARO Arm to ensure products adhere to original CAD specifications.