2D Laser Scanning/Inspection & Reverse Engineering

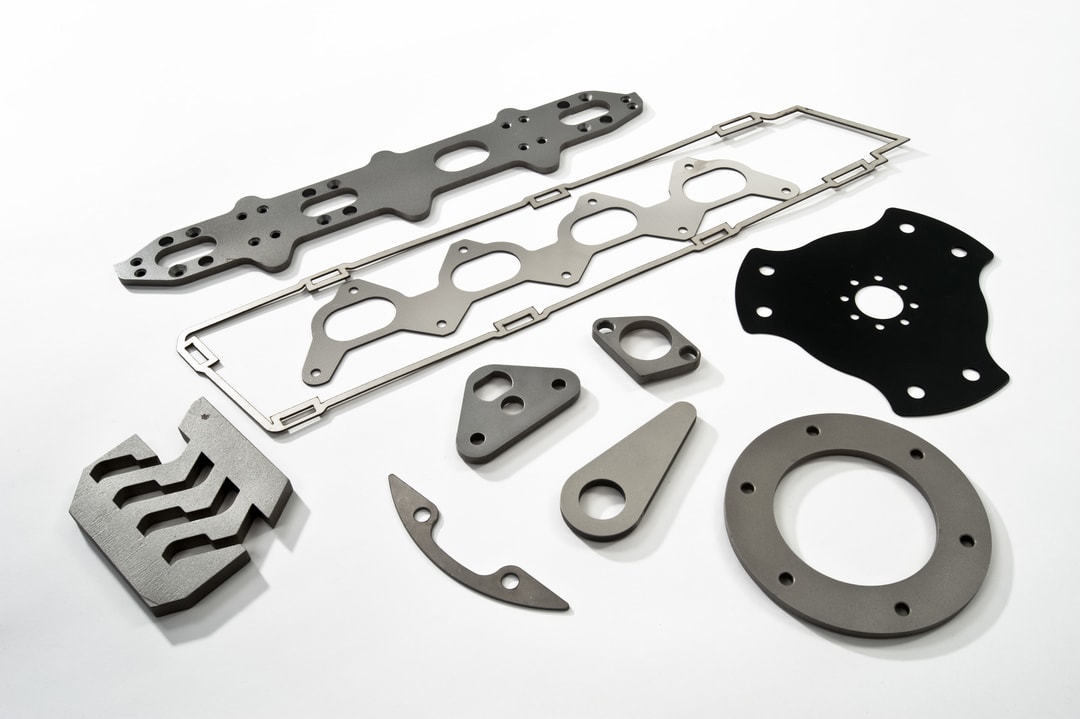

2D Laser Cutting Services

3D Laser Scanning/Inspection & Reverse Engineering

3D laser Cutting Services

CAD/CAM

CO2 Laser Cutting

Etching

Machining

Metal Finishing

Fiber Laser Cutting

Our Service Offering

With all of these services, we are confident that we can offer a comprehensive manufacturing process from the initial design to the finished product.

We work on projects from all sorts of different sectors and have built a wide portfolio of experience over the years. Our highly trained staff will be able to offer advice on your particular project and guide you through the whole process.

If you have a laser cutting project, please get in touch today to discuss your requirements.