Laser Cutting for Stainless Steel

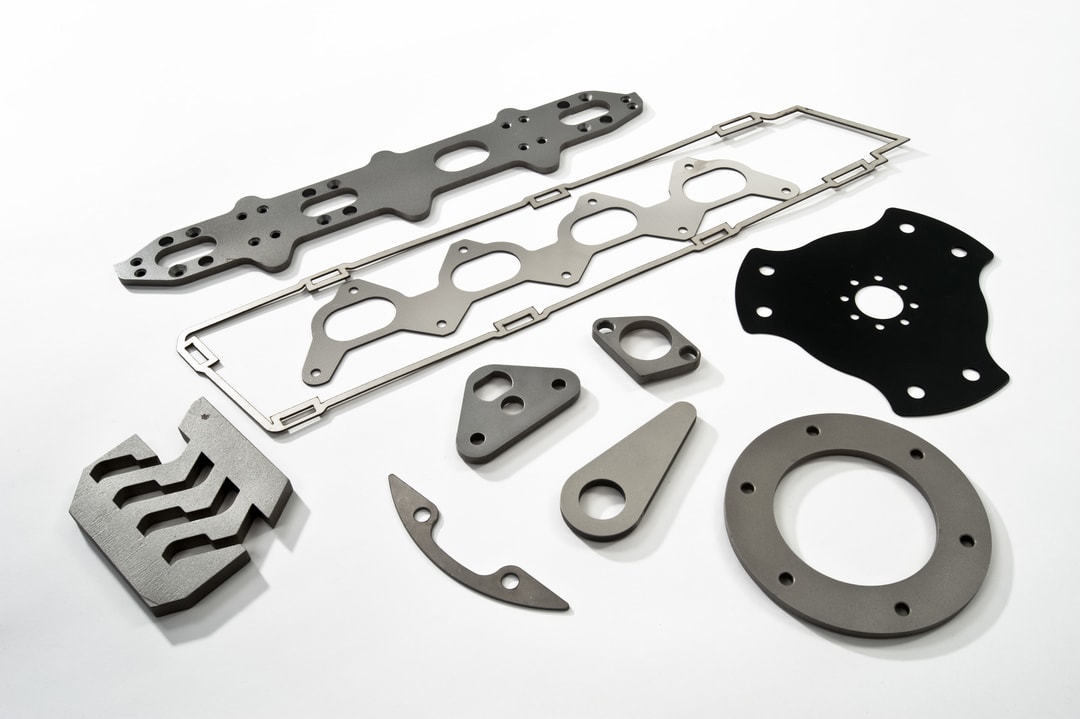

We have the ability to laser cut stainless steel in all grades, from common grades for a variety of applications to specialist stainless steels for exacting performance.

Subcon Laser provides a comprehensive service for the production of stainless steel parts and components. Specialising in laser cutting, our state-of-the-art equipment facilitates a range of laser cutting operations, and our capabilities for this includes:

- Tolerances from +/-0.12mm to 0.5mm, depending on material thickness

- Stainless steel thickness from 0.5mm to 50.0mm

- Maximum material dimensions of 4000mm x 2000mm

Our experienced team further offers secondary operations, including bending, forming, bevelling, deburring, welding and more, ensuring a complete production process.

Subcon Laser has the industry experience and knowledge to carry out our clients’ projects to completion, from simple laser cutting operations to complex solutions, for projects large and small.

Stainless Steel Grades

Subcon Laser holds stainless steel in grades 304, 304L, 316, 316L, 401, as well as 3CR12.

The specialist stainless grades we work with include: 316Ti, 321m 430, duplex, super duplex, shim steel, Incoloy® Alloys and Hastelloy® Steel.

Our grades provide an exceptional range of properties and characteristics, offering differing chemical compositions to fulfil strength requirements, durability, corrosion resistance, weight and other specifications.

Finishes

We offer a number of widely used finishes complementary to stainless steel. This includes cold rolled 2B, hot rolled, dull polish, and mirror polish.

2B cold rolling is a popular finish for stainless steel, ensuring the product achieves a smooth, corrosion-resistant finish with moderate reflection. Further processing can be undertaken with this finish.

Our hot rolling finishes achieve good corrosion resistance and a non-reflective finish. Further processes can be performed to meet requirements.

Dull polishes, or grained finishes, remove minor surface defects and are suitable for products where appearance is a significant factor.

Mirror polish is available for products that prioritise appearance, with a bright, reflective finish. Mirror polishing further ensures the product is free from contaminants, making it ideal for sectors where hygiene is critical.

Our Stainless Steel Service

Our stainless steel 2D and 3D parts are suitable for all applications. Subcon Laser works closely with the automotive sector, marine, architectural, rail and many more to provide stainless steel parts and components.

If you’re looking for another material, take a look at our capabilities for laser cutting: