Laser Cutting Bronze

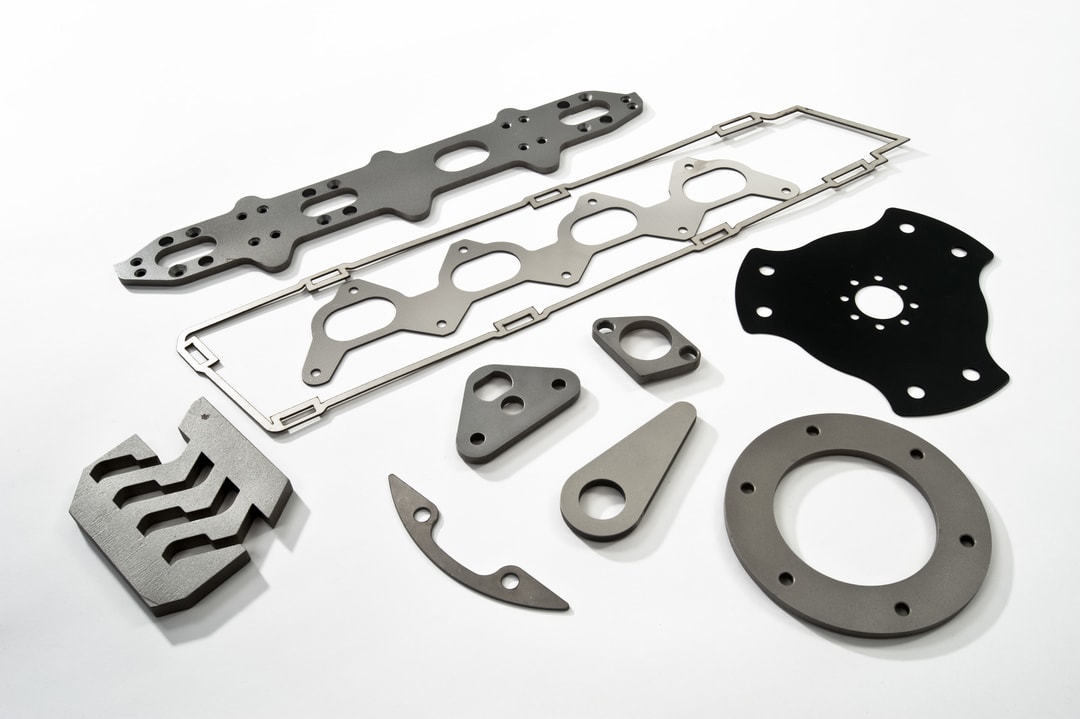

Subcon Laser’s wide-ranging laser cutting and fabrication departments are suitable for the working of bronze sheet, ensuring we can provide bronze parts as required by your unique project specifications.

We stock PB103 phosphor bronze for use in our operations, offering a higher tin content for improved strength and corrosion resistance in a wide range of applications.

Our outstanding service encompasses laser cutting and secondary fabrication services to tight tolerances, ensuring we can deliver a finished product that is fabricated and formed to custom specifications.

Our deep industry knowledge and familiarity with a variety of materials ensure Subcon Laser can engage with all projects, guiding our customers as required to ensure the most efficient and effective production process.

Bronze Grades

Subcon Laser holds PB103 phosphor bronze in stock. This copper alloy contains 6% tin and a small percentage of phosphor.

Bronze is known for its reduced brittleness and improved hardness and durability compared to copper and tin. Phosphor bronze in particular offers increased strength, wear resistance, and durability; it is suitable for high wear parts due to its fatigue resistance.

Our bronze components find use within industries including marine, power generation, architectural metalwork, and more. The excellent corrosion resistance of bronze means it performs well in wet and corrosive environments.

Subcon Laser has a wealth of experience working to the standards and specifications of a range of industries, including ISO quality standards, with our service seeking to understand and meet our clients’ unique requirements.

Brass vs Bronze

As two alloys of copper, brass and bronze both offer advantages as manufactured components. Whilst brass offers malleability and good corrosion resistance, it does have a lower melting point than bronze.

Bronze is a harder material, with greater corrosion resistance than brass.

Subcon Laser holds both brass and bronze in stock. If you’re considering which material is most suitable for your project, our expert team can offer guidance as to material feasibility and efficiency.